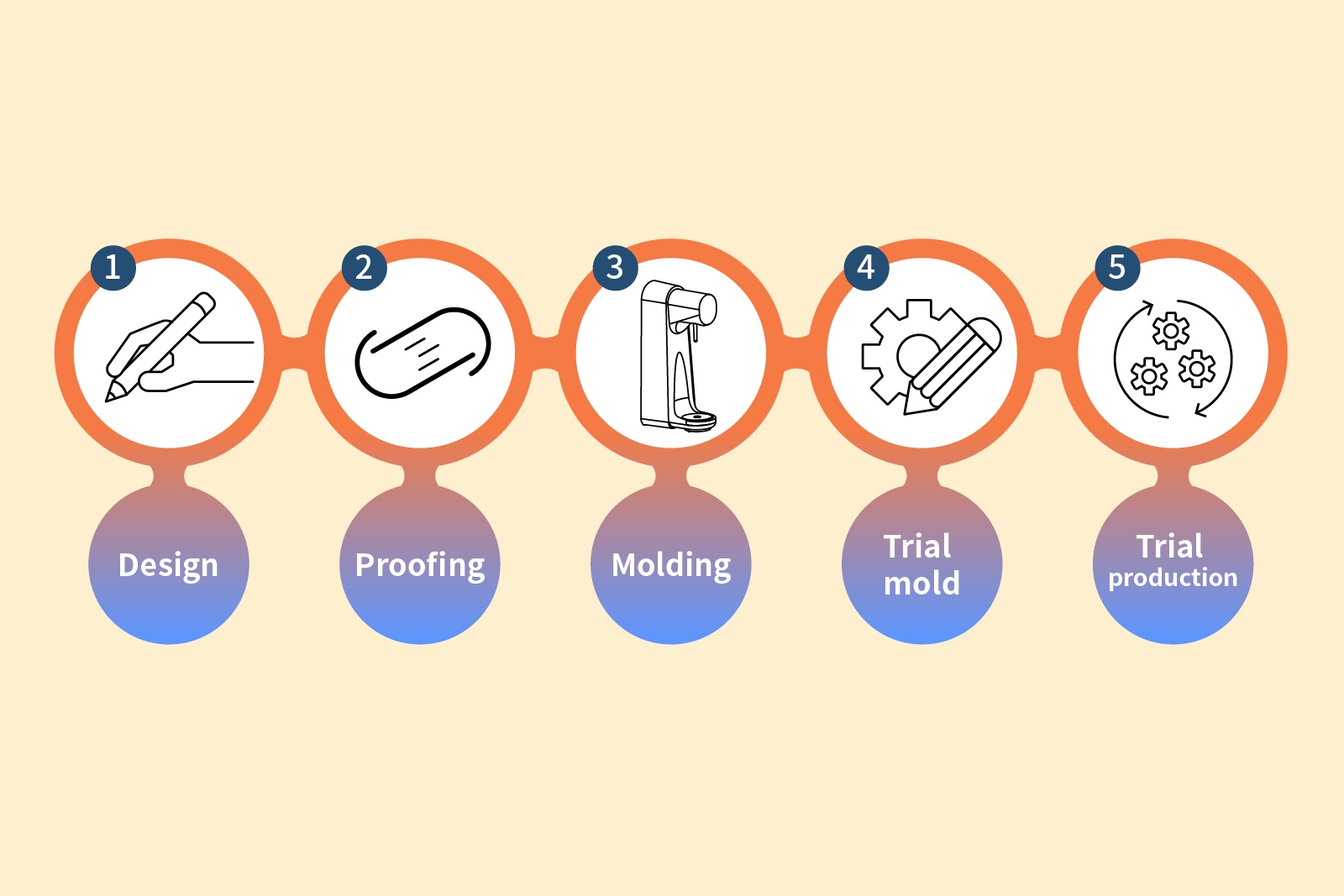

Hongfeng is a professional soda maker manufacturer. We will introduce you to the entire process of soda maker production, from design, proofing, molding, trial molding to trial production, so that you can understand the precision craftsmanship and strict processes behind soda maker.

We have a professional design team that continuously innovates and improves based on market demand and consumer feedback. Designers will make preliminary conception and design based on the product's functional and appearance requirements. At this stage, the practicality, aesthetics and manufacturing feasibility of the product will also be considered.

Once the designers complete the preliminary design, we will first produce samples. These samples will be used for subsequent testing and evaluation to ensure product quality and performance meet requirements. During the prototyping process, engineers will make many adjustments and improvements until the desired effect is achieved.

At this stage, raw materials are transformed into final product form through our professional equipment and processes. The molding process requires strict control of parameters such as temperature, pressure and time to ensure product quality and consistency. At the same time, our staff will also inspect and trim the formed products to ensure that each product meets the standards.

At this stage, we will use a small-scale production line for trial mold production. Through trial molding, engineers can check and adjust various parameters during the production process to ensure product quality and stability. At the same time, they will also conduct rigorous testing and evaluation of the products produced from trial molds to identify potential problems and make improvements.

After the mold trial is successful, we will conduct trial production to verify the feasibility of the entire production process and the quality of the product. During the trial production process, engineers will adjust and optimize the production line to improve production efficiency and product quality. At the same time, comprehensive testing and evaluation of trial production products will be carried out to ensure product performance and reliability.

We can complete the above processes within 90 days at the earliest. At the same time, we will continue to innovate and improve to provide consumers with better products and services.